MechEase Training Institute is a leading BIW Product Design Training Classes in PCMC, Akurdi, Ravet, Nigdi and one of the best BIW Product Design Placements in PCMC . We give a comprehensive and deeper understanding of the important and structural points that are included while manufacturing the Body-in-White (BIW) product design.

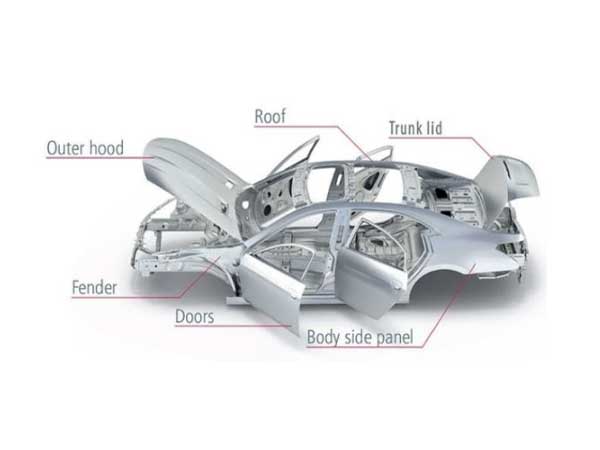

The BIW term refers to the development and engineering of structural components of a vehicle's body before painting and assembly. We are known for the best BIW Product Design Courses in PCMC, Akurdi, Ravet, Nigdi that give you detailed and valuable information or skills that are required for manufacturing and designing automotive body components. It is the one-stop solution for getting all the structural skills and knowledge about BIW product design.

We have included important and necessary topics in our BIW Product Design Course in PCMC,Akurdi, Ravet, Nigdi which will help you to build higher and new skills about structural component of automotive parts. Here we have listed down below all topics covered in our course:

We have included important and necessary topics in our BIW Product Design Courses in PCMC,Akurdi, Ravet, Nigdi which will help you to build higher and new skills about structural component of automotive parts. Here we have listed down below all topics covered in our course:

MechEase Training Institute is a former BIW Product Design Classes in PCMC, Akurdi, Ravet, Nigdi and our primary motive is to empower students with higher knowledge and skills in the automotive industry. This comprehensive course will guide you through every minute and critical aspect of BIW, from the basis of vehicle body design to the advanced assembly process and quality checks. We ensure that learners are fully capable of taking any industry challenge because we guide them with multiple skills, such as real-world case studies, interactive modules, and hands-on practice.

| UnitTitle | Title |

|---|---|

| Body type | 1) Monocoque 2) Body on frame |

| Material used in BIW | 1) Steel 2) Aluminum 3) Carbon fiber reinforce plastic |

| Design consideration | 1) Aerodynamic & good appealing shape of overall BIW structure 2) BIW must be corrosion resistant & law weight 3) Sufficient space for occupant/load caring capacity 4) Overall structure stiffness & strength should be good enough to perform On road testing parameters. |

| Underbody structure |

| Body side structure |

| Front end structure |

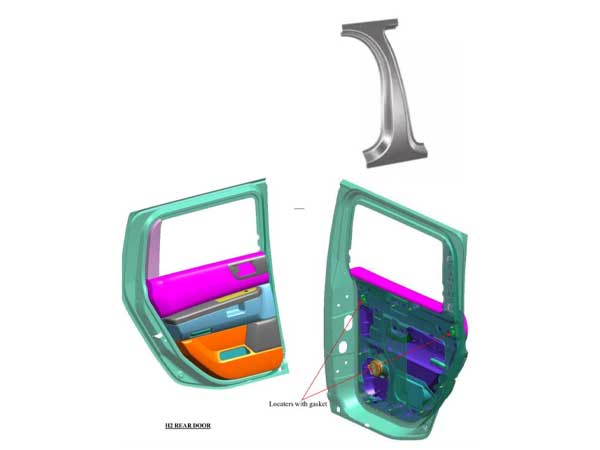

| Closures |

| Roofs |

| Fenders |

| Reinforcement |

| Pillars – A,B,C,D |

| Front panels (fire wall) |

| Dashboard mtg. panel |

| Cant rail |

| Roof structure |

| Side sill |

| Front cross-member |

| Floor |

| Center tunnels |

| Front and rear wheel arch |

| Spot Weld | a) 2 Metal Joint b) 3 Metal Joint Spot weld perform with spot weld machine by melting Body panel material local Point of two OR three panel to be weld |

| Projection Welding | This type of welding example is Nut welding on panel with weld Nut projection give in nut which melt at the time of projection welding. |

| Flange Heming | In this type o joining main panel flange folded around another panel such as join these two pars same as welding |

The course typically lasts for 3 to 6 months, depending on the student's learning pace and the training mode (full-time or part-time). We also offer flexible scheduling for working professionals.

A basic understanding of mechanical engineering or CAD software is helpful, but not mandatory. We have specially designed this course to accommodate both beginners and professionals looking to increase their skills in BIW design.

We provide hands-on training in industry-standard software such as CATIA, NX, and AutoCAD, which are essential for BIW design and product development in the automotive industry.

Yes, students will work on live BIW design projects, simulating real-world scenarios to apply their theoretical knowledge practically. This overall structural guidance will be useful for students for building a strong portfolio in their future job applications.

Absolutely! We offer dedicated placement support, resume-building workshops, and interview preparation sessions to help students secure positions in top automotive companies.